Horizontal End Suction Process Pumps

Capacity (Maximum) 1000 m'/hr.

Capacity (Maximum) 1000 m'/hr. Head (Maximum) 140 m

Head (Maximum) 140 m Temperature 160° C

Temperature 160° C Working Pressure kg/cm' 14 kg/cm

Working Pressure kg/cm' 14 kg/cm

Special Features

Jacketed convertible stuffing box utilizing gland packing or mechanical seal.

Jacketed convertible stuffing box utilizing gland packing or mechanical seal. Special designed stainless steel impeller nut with helical spring insert to lock the impeller properly.

Special designed stainless steel impeller nut with helical spring insert to lock the impeller properly. Back pull out type bearing frame assembly.

Back pull out type bearing frame assembly. Mechanically & hydraulically balanced impeller for long life and high efficiency performance.

Mechanically & hydraulically balanced impeller for long life and high efficiency performance. Heavy duty shaft with maximum deflection less than 0.05mm.

Heavy duty shaft with maximum deflection less than 0.05mm. Heavy sections to withstand high pressure and temperature.

Heavy sections to withstand high pressure and temperature.

Design Features

Shaft Design :

Designed for toughest services. Maximum 0.05 mm deflection at stuffing box face at maximum load.

Balancing of Impeller :

Hydraulically and Mechanically Balanced Impeller. Axial thrust balance achieved by front and back wearing rings with balancing hole / back vanes for operation over wide range of suction pressure.

Versatile Shaft Seal :

By gland packing. Option to use standard unbalanced / balanced mechanical seal.

Robust Deep Groove Ball Bearings :

High operating reliability, grease / oil packed.

Better Interchangeability :

Ensures fast delivery and low inventory.

High Performance :

Lower noise and less vibration levels

Mechanical Seals :

Various mechanical seal configurations are available. A single mechanical seal is used for many applications with no circulation liquid, flushing with internal / external circulation liquid or with grease is available. For extremely demanding liquids and application, double mechanical seals can be selected. Sealing liquid from an external source is required.

Gland Packing :

Gland packing with external flushing prevents the pumped liquid from penetrating into the seal housing. The pressurized flushing liquid causes it to flow into the pumped liquid. Alternatively the external flushing liquid can have a separate outlet connection.

Salient Features

Back pull out design permits quick and easy access to rotating parts without disturbing suction and discharge pipes, electric motor, its connections and alignment. Low maintenance, inventory and standardization because of module system. The pump is designed to achieve a low NPSH requirement and high efficiency. It is rugged in construction and is versatile in application. This series is designed in accordance with ISO 5199 / ISO 2858, making it ideal for worldwide chemical or industrial process applications.

Areas of Application

Condensate

Condensate Service Water

Service Water Injection / spray

Injection / spray DM Water Transfer

DM Water Transfer

Chemical Transfer

Chemical Transfer Circulation

Circulation Portable water

Portable water

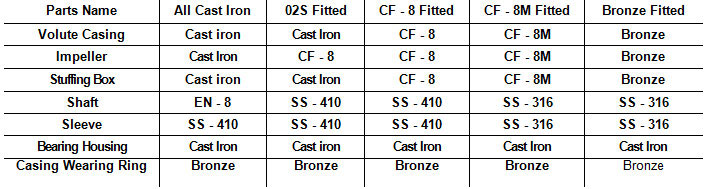

Construction Material

Pumps are also available in Cast Steel, Ni-Resist, Super Duplex, CN7M, Haste Alloy and other special stainless steel alloys in addition to mentioned above. The materials of construction are indicated as an example of generally accepted practice, but are not intended as recommendations of fitness for a particular purpose. The customer must determine and take the ultimate responsibility for specifying the proper materials to handle the particular fluid pump. Unless otherwise specified, all pumps shall be furnished with the standard fitted materials to meet the system requirement.