Vertical Sump Pumps

Capacity (Maximum) 1,000 m/hr.

Capacity (Maximum) 1,000 m/hr. Head (Maximum) 100 m

Head (Maximum) 100 m Temperature 80° C

Temperature 80° C

Special Features

Vertical pumps take little space in plan since the liquid is led away to the axis of shaft.

Vertical pumps take little space in plan since the liquid is led away to the axis of shaft. The impeller is submerged, so pump does not required to be primed and is always ready for use.

The impeller is submerged, so pump does not required to be primed and is always ready for use. The positive suction condition also prevents the cavitations in the pump and pitting in impeller and

diffuser.

The positive suction condition also prevents the cavitations in the pump and pitting in impeller and

diffuser.

Due to positive head at suction the pump gives its rated performance as well as high overall efficiency.

Due to positive head at suction the pump gives its rated performance as well as high overall efficiency.

Design Features

Glandless type and / or vapour sealing type execution available. In vapour sealing design, the gland and acid resistant asbestos packing prevents the leakage of vapours of hazardous liquids from coming out. Thus the environment is kept free from pollution and dangerous inflammable obnoxious liquids. Very rigid construction with extra wall-thickness provided for corrosive where fluctuations in liquid levels are considerable. The pump unit is suspended by a column pipe applications. It is virtually maintenance free. Vertical pumps are best suited for wet pit applications which also protects the transmission shaft and is submerged in the liquid to be pumped. These pumps require small floor area and can be started without priming. Discharge / Suction flanges conforms to ASA / DIN / BS standards.

Delivery CASING :

The delivery casing has an area sufficient enough to ensure easy passage of liquid with optimum efficiency.

IMPELLER :

The delivery casing has an area sufficient enough to ensure easy passage of liquid with optimum efficiency. Impeller : Impellers are enclosed / semi-open / open with large passage ways and thickened vanes at the inlet. All impellers are dynamically balanced. Closed type and semi-open type impeller designs are offered to handle a variety of liquids. Impeller are designed for maximum hydraulic efficiency and minimum thrust on rotating assembly. Unique space-saving design due to vertical mounting of pump. Impeller and casing are totally submerged in liquid so no priming or air venting is required. Inside tank and outside tank mounting designs available for respective applications.

Pump Shaft :

The pump shafts are of high tensile carbon steel and designed for high torque transmission. Stainless steel shafts can be provided against requirement. The bearing areas are protected by stainless steel sleeves. Intermediate, line and head shafts are of ample strength and rigidity. Minimum bearing span is adopted to keep deflection and vibration to a minimum.

Line Shaft / Intermediate Shaft :

Line shafts / intermediate shaft of high tensile carbon steel designed for high power transmission are connected by intermediate couplings and run in closely spaced bearings for vibration-free operation.

Motor Stool :

The heavy duty cast iron / mild steel motor stool is capable of taking the motor and rotor assembly weights as well as the axial thrust. It also houses the thrust bearings.

Intermediate Bearings :

The transmission bearings may be lubricated by one of the following methods:

1. External supply of clear cold water.

2. By liquid being pumped.

3. Grease External clear water lubrication is recommended when it is available at a pressure higher than the discharge pressure of the pump. If the pumped liquid has a turbidity of less than 50 ppm (silica scale) or 500 ppm (chloride scale) and total solids less than 3000 ppm with pH value between 6.5 and 8.5, then it may be used as the lubricating liquid. Grease lubricated bearings are recommended when external or self lubrication is not possible. Grease is supplied by a grease pump driven either through the pump coupling or by a separate motor. Angular contact ball bearing at the top to take residual axial thrust and the weight of rotating parts.

Delivery Pipe :

Heavy duty delivery pipe upto the motor stool floor level with one bend is standard supply with all.

Accessories :

The following accessories are recommended.

1. Screens at inlet of the sump to prevent solids of sizes larger than that recommended from entering the pump.

2. Liquid level controllers to guard against dry running of the pump.

3. Power operated positive displacement grease lubricator for grease lubricated pumps.

4. Delivery pipes and bend upto the motor stool.

Salient Features

Compact design, easy to install

Compact design, easy to install Extra heavy shaft

Extra heavy shaft Screenless, chockless and glandless design

Screenless, chockless and glandless design Also available in dry pit designs

Also available in dry pit designs

Areas of Application

Dewatering applications where water is contaminated with solid particles

Dewatering applications where water is contaminated with solid particles Raw sewage, slurry

Raw sewage, slurry Effluent, industrial waste transfer in industrie's Waste water

Effluent, industrial waste transfer in industrie's Waste water Drainage of basements, tunnels, boiler rooms

Drainage of basements, tunnels, boiler rooms Storm water

Storm water

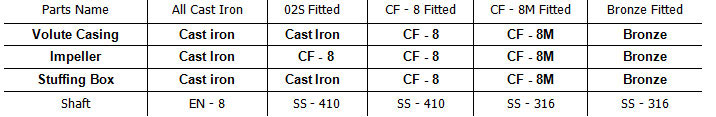

Construction Material

Other than above stated material pumps are available in Cast Steel, CA 15, Ni-Resist, Super Duplex, CN7M, Haste alloy and other special stainless steel alloys. The materials of construction are offered as an example of generally accepted practice, but are not intended as recommendations of fitness for a particular purpose. The customer must determine and take the ultimate responsibility for specifying the proper materials to handle the particular fluid pumped. Unless otherwise specified, all pumps shall be furnished with the standard fitted materials to meet the system requirement.